AJP is a company specialized in coating (plastic coating, plastic coating) in the North of France. Our machine park and our know-how allow us to work with jumbo paper or plastic reels for cutting and coating. AJP prepares reels for its customers in the required format and with the required coating treatment.

AJP has a state-of-the-art coating machine for polyester, polyethylene, polypropylene and paper films. We coat a wide range of films and papers according to your technical requirements.

For any advice or price request, contact us!

We support you in the development of your customized and durable products in many industries. Our chemists develop ink carrier coatings that guarantee ideal drying and gloss for your prints due to their excellent properties. We carry out all pre-industrial tests and trials before the final production run.

Our quality control checks the parameters of compliance with the deposited weights (from 1 to 27 gr), surface homogeneity, and intrinsic qualities of the final coated product.

Our significant investments in solvent and chemical treatment allow us to be environmentally compliant.

The AJP range of products and films are treated to give them stability, breathability, adhesion and printability.

AJP has the possibility to make them glossy, matt, opaque, white… according to the desired needs. Thus, the quality of the final image is optimized.

Our media are adapted to numerous needs in all sectors of activity, such as heat-resistant technical PVC labels, textile and leather transfers, technical printing media, thermo-adhesive papers for the food industry, roofing undersides, fluorescent posters (or others) for distribution, tarpaulins, etc. ….

We are also manufacturers of special in mould label and can meet all the needs of industrialists.

Coating paper or cardboard has many applications, to provide a colour, a texture with anti-slip, printable and water-repellent properties. The possible uses of coated papers are very varied, such as fluorescent posters, hydrophobic papers, anti-slip sheets for pallet interleaving, paper sheets for the food industry.

Thanks to its high-performance coating machine, AJP applies a primer to all types of plastic film. Similarly, our technology and know-how in chemical products allow us to apply colouring to the plastic film, such as fluorescent inks for example.

Companies that extrude plastic films call on AJP to apply a primer or other coating that improves the surface properties of the film, improving its appearance, adhesion, UV resistance, ink adhesion, or to adjust the surface properties, once coated, to mechanical constraints and the various elements of the external environment (UV, temperature, humidity, oxidation, etc.). Learn more about plastic coating.

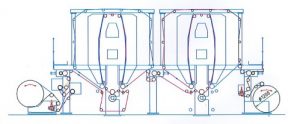

Coating on flexible paper or plastic requires a coating machine. AJP has the latest generation of water-based or solvent-based coating machines, which provide optimum performance.

The coating process consists of coating a substrate to give it one or more new mechanical properties for indoor and outdoor use.

These properties are numerous: making a coating printable, offering very good water resistance, antistatic, heat-weldable to allow parts to be assembled, etc. For example, textile coating is a surface treatment used in particular for technical textiles, which are used in the manufacture of tarpaulins or flexible tanks.

Coating is used in many other sectors of activity and on various paper or plastic coatings, for example for the production of cardboard packaging, double-coated labels, bandages, adhesive tape, etc.

Coating is often a production step that can be carried out by a subcontractor. A subcontracting service, where the company receives the material to be coated, often in the form of paper or PVC jumbo reels (polyethylene PE, high density polyethylene HDPE, polypropylene PP, polyethylene terephthalate PET plastic film).